Reverse Vending Machine

Reverse Vending Machine (RVM) is an automated recycling solution designed to encourage the disposal of empty PET (polyethylene terephthalate) bottles and other beverage containers. It operates on a simple yet effective principle-

Consumers insert their used plastic bottles into the machine, which then processes them for recycling. The RVM is equipped with an internal crusher that immediately compresses the bottles, significantly reducing their volume. This compaction minimizes the space required for storage and transportation, these machines also contribute to environmental sustainability by promoting circular economy principles, reducing plastic pollution and encouraging consumer participation in responsible waste disposal

What is a Reverse Vending Machine (RVM)?

A Reverse Vending Machine (RVM) accepts empty PET bottles and rewards users with incentives, such as refund value or green points, which are linked to their mobile number. These rewards can be redeemed at stores or online,and sometimes donated to charity. Simply insert the bottle, enter your mobile number, and earn benefits for recycling.

Features

-

Environment

• 100% recycling • Reduction in CO2 emission • Reduction in water consumption in cleaning

-

Sustainability

• Reduce in transport cost due to volume reduction at source • Reduce excess fuel consumption in transport and virgin material • Source segregation, Efficient Handling, bottle to bottle grade quality

-

Governance

• Transparent collection and processing • Online tracking /utilization • Reduction in unorganized sector /child Labour

-

Economical Process

• Built on Crushing • Technology Volume Reduction at sourceup to 70% • Most economical Recycling Process • Highly Scalable

-

User Friendly & Easy to Maintain

• Plug & Play machine • User friendly –Automated • Drop & Recycle machine • Customisable reward system • Customisable Screen displa

360 solution for Plastic Waste at source

Features

- Weight: 300 kg

- Body: MS, powder coated

- Crush Bottle & Cans

- Green Powder Coated

Bottle Size

- 50mm to 400mm

- only Beverage container like Water, Juices and soft drinks

Power Requirement

- Single Phase

- Power: 230 V

- Install one MCB switch near machine

Connectivity

- Wi-Fi Network

- API-Based Data Integration

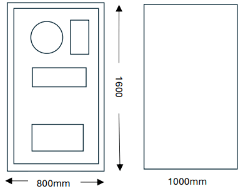

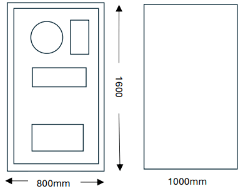

Dimensions

User Interaction

- 20” Screen in Front for Content Display with Sound – Customizable, User Guide on Display

- Running Video/Messages/Advertisement

- Designer Flex from All Sides of Machine

360 solution for Plastic Waste at source

Dimensions

Features

- Weight: 300 kg

- Body: MS, powder coated

- Crush Bottle & Cans

- Green Powder Coated

Bottle Size

- 50mm to 400mm

- only Beverage container like Water, Juices and soft drinks

Power Requirement

- Single Phase

- Power: 230 V

- Install one MCB switch near machine

Connectivity

- Wi-Fi Network

- API-Based Data Integration

User Interaction

- 20” Screen in Front for Content Display with Sound – Customizable, User Guide on Display

- Running Video/Messages/Advertisement

- Designer Flex from All Sides of Machine

Bottle Size

- Can take bottle up to 2 ltr size

- 50mm to 400mm

- only Beverage container like Water, Juices and soft drinks

Power Requirement

- Single Phase

- power 230 V– 1 phase

w/ground 50Hz, 1440

RPM 22 amps - Install one MCB switch

near machine

Connectivity

- Wi-Fi network

- Local SMS service

provider - API based data

integration

User Interaction

- 20” screen in front for content display with sound–customisable ,User Guide on Display

- RunningVideo/Messages/advertisement

- Designer Flex from all side of Machine

Role of RVM

- Encourage Recycling

- Environmental Impact

- Resource Recovery

- Promote Circular Economy

- Incentivize Participation

- Data Collection & Monitoring

- Public Awareness

Role of RVM

- Encourage Recycling

- Environmental Impact

- Resource Recovery

- Promote Circular Economy

- Incentivize Participation

- Data Collection & Monitoring

- Public Awareness

Conclusion

Plastic bottles are a major environmental issue, but Reverse Vending Machines (RVMs) offer a solution by incentivizing recycling. RVMs encourage consumers to return bottles, helping reduce litter,conserve resources, and lower greenhouse gas emissions.

Key Benefits

- Increased Recycling Rates: RVMs can boost recycling rates by up to 50%

- Reduced Litter: RVMs help decrease plastic bottle litter in public areas and oceans.

- Conservation of Resources: Recycling bottles with RVMs conserves water and energy

- Lowered Greenhouse Gas Emissions: RVMs reduce the need for new plastic, cutting emissions

Conclusion

Key Benefits

- Increased Recycling Rates: RVMs can boost recycling rates by up to 50%

- Reduced Litter: RVMs help decrease plastic bottle litter in public areas and oceans.

- Conservation of Resources: Recycling bottles with RVMs conserves water and energy

- Lowered Greenhouse Gas Emissions: RVMs reduce the need for new plastic, cutting emissions